Upgrade Demands for Overhead Distribution Systems and the Rise of ABC Cables

Overhead distribution serves as the “last mile” connecting substations to end-users, directly impacting power supply stability and safety. While traditional bare conductors are simple and inexpensive, they present significant drawbacks: susceptibility to electric shocks and short circuits from accidental contact or tree branch contact; high vulnerability to severe weather and frequent outages; visual pollution in densely populated urban areas due to haphazard installation; and difficulty in maintaining safe distances from buildings and facilities.

ABC cables represent an overhead cable system where multiple insulated conductors are bundled together with a neutral carrier wire. By encapsulating conductors within insulation, they eliminate the inherent safety hazards of bare wires while offering compact structure, flexible installation, and simplified maintenance. In recent years, driven by urban-rural grid upgrades, growing renewable energy integration demands, and enhanced safety standards, ABC cable adoption has grown at an average annual rate exceeding 15%. Widely deployed in retrofitting aging residential areas, rural electrification, and industrial park power distribution, it has become the preferred solution for overhead distribution upgrades.

Understanding ABC Cable: Definition, Structure, and Core Standards

Core Definition of ABC Cable

ABC cables, fully known as Aerial Bundled Cables, are insulated cable systems specifically designed for aerial installation. Their core feature is the “bundled installation of multiple insulated conductors + neutral carrier wire for load-bearing.” Beyond power transmission, their integrated design simplifies overhead line structures, significantly enhancing safety performance and environmental adaptability.

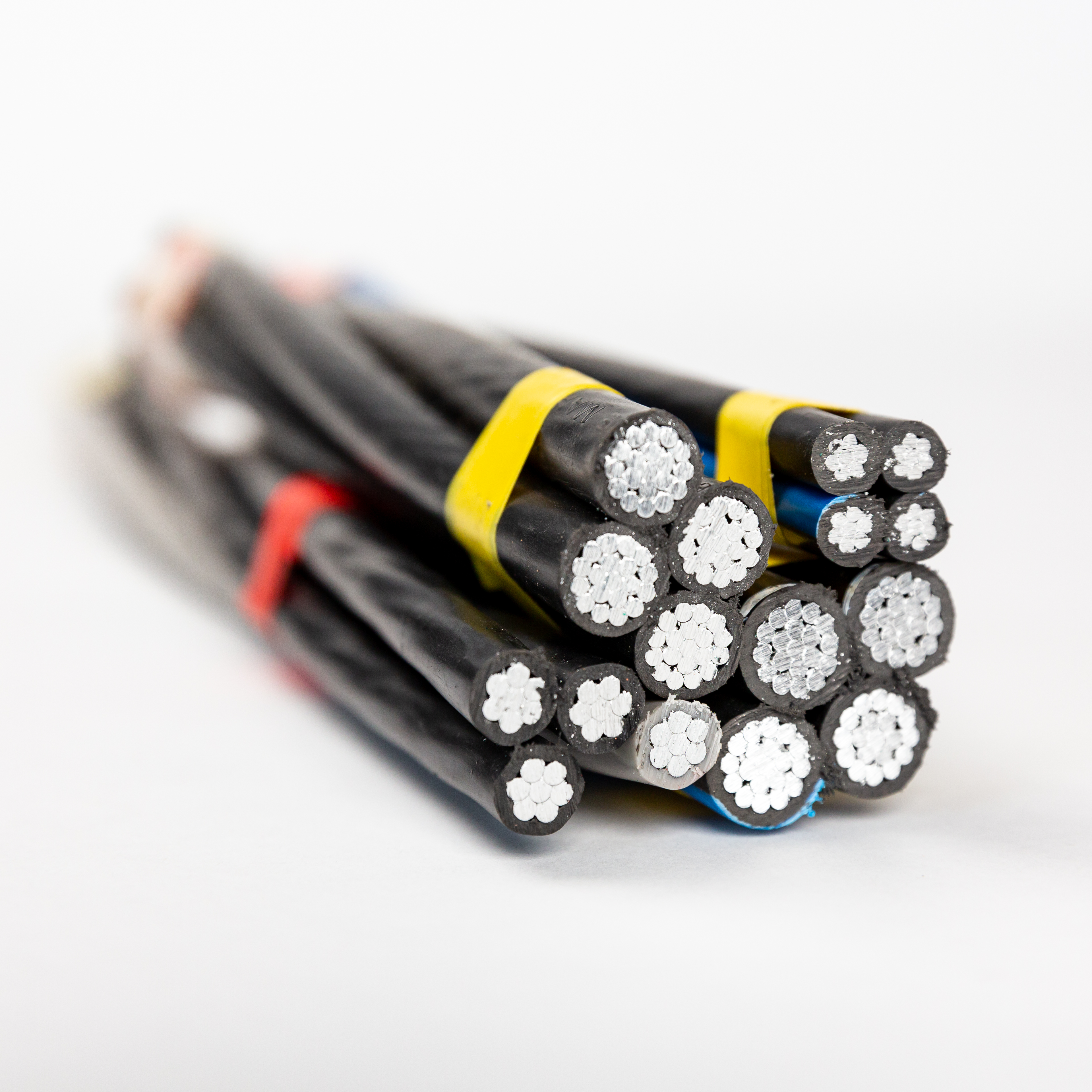

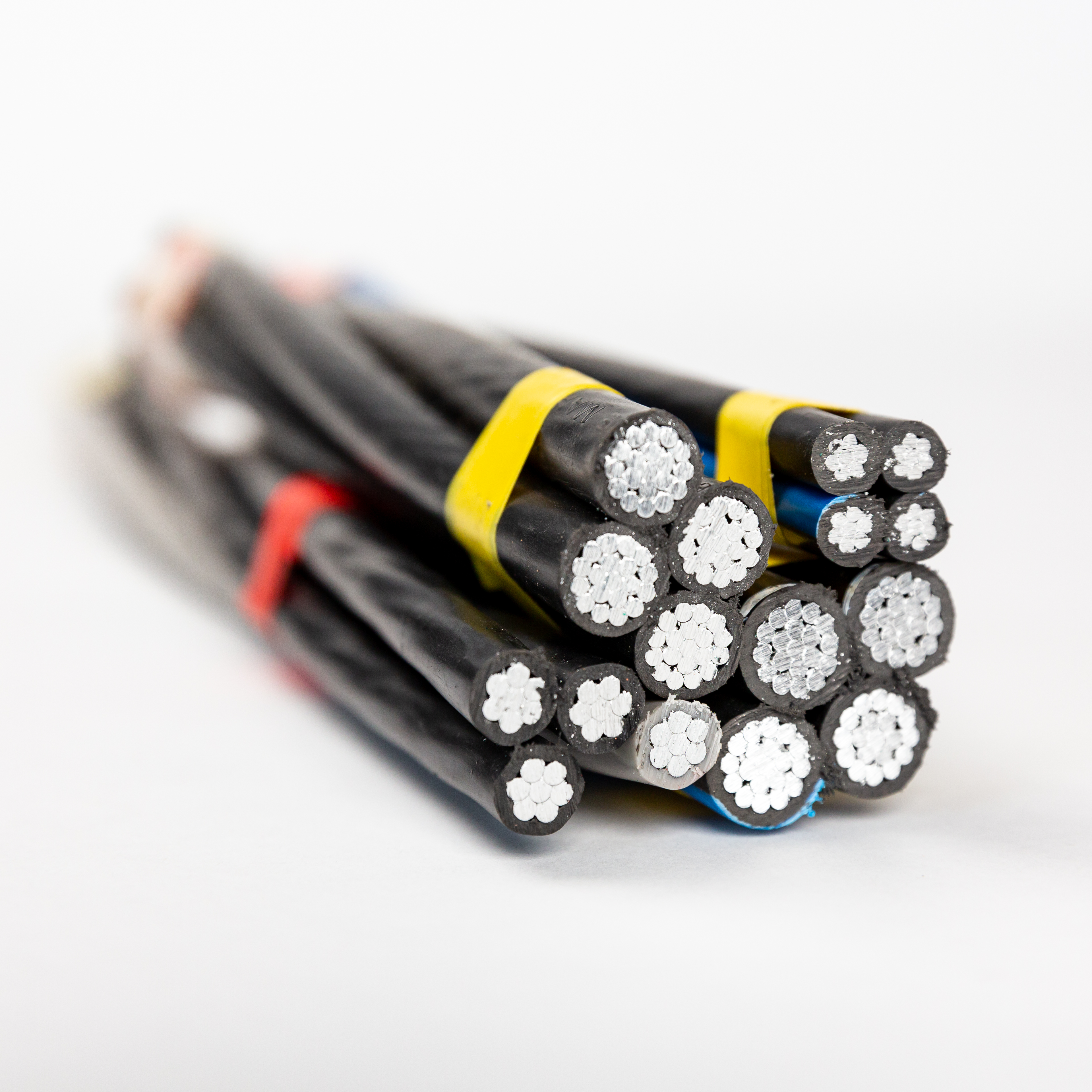

Basic Structure of ABC Cable

The standard ABC cable structure primarily consists of three components, each working synergistically to ensure stable line operation:

Insulated Phase Conductors: The core transmission unit, typically made of copper or aluminum (aluminum conductors are more widely used due to their lightweight advantage), with cross-sectional areas ranging from 16-240mm² based on current-carrying capacity requirements; - Insulation: Primarily XLPE (cross-linked polyethylene) or PVC (polyvinyl chloride). XLPE insulation withstands temperatures of 90-125°C, offering superior aging resistance and weatherability, suitable for medium/high voltage and harsh environments. PVC insulation is cost-effective with a temperature rating of 60-70°C, commonly used in low-voltage residential applications.

Neutral Carrying Conductor: Bears the entire line tension to ensure stability in overhead installations. Materials typically include high-strength aluminum-clad steel strand (ACSR) or pure aluminum strand. Some premium products utilize carbon fiber composites to further enhance tensile strength while reducing weight. This conductor also serves as the neutral conductor for power transmission, fulfilling dual functions of load-bearing and electrical conduction.

Optional lighting conductor: Some ABC cables integrate a dedicated conductor for streetlight power supply, eliminating the need for separate lighting lines and simplifying municipal distribution project construction.

Common Voltage Ratings and Core Standards

ABC cables primarily cover low-voltage and medium-voltage distribution applications, adapting to diverse power supply requirements:

Low-voltage ABC cables: Rated at 0.6/1kV, the most widely used type. Suitable for residential distribution, rural grids, and small commercial facilities, supporting single-phase 220V or three-phase 380V systems.

Medium-voltage ABC cables: Rated at 3.6-35kV. Used for urban distribution network trunk lines and industrial park power distribution, enabling medium-distance, high-capacity power transmission.

The production and application of ABC cables must comply with stringent international and regional standards to ensure safety and reliability:

International Standards: IEC 60502 (low-voltage cable standard) and IEC 60840 (medium- and high-voltage cable standard) define core parameters such as conductor performance, insulation thickness, and mechanical strength for ABC cables.

- Regional Standards: French NFC 33-209, American ASTM standards, Chinese GB/T 12706, etc., refine product technical requirements based on regional climatic conditions and distribution needs.

Advantage 1: Ultimate Safety, Mitigating Electric Shock and Short-Circuit Risks

Safety is the core strength of ABC cables. Their insulated design fundamentally resolves the safety concerns associated with bare conductors, significantly reducing the risk of electrical accidents.

Insulation Protection Reduces Electric Shock Risk

Traditional bare conductors pose electric shock hazards from accidental human contact or animal climbing. ABC cables feature insulated phase conductors (insulation resistance ≥10¹⁴Ω·cm), effectively isolating current and reducing shock risks by over 90%. This offers significant advantages in densely populated urban areas and school surroundings.

Reduced Short-Circuit Failures for Stable Power Supply

Bare wire short circuits often result from conductor or foreign object contact. ABC cable insulation effectively isolates phases, reducing short-circuit failure rates to one-fifth of bare wires. Annual failure frequency drops from 3-5 per kilometer to 0.5-1 per kilometer, ensuring stable power supply.

Reduced Fire Hazards and Adaptability to Special Environments

In forested or arid regions, arcs from bare conductors can easily ignite fires. The flame-retardant insulation of ABC cables blocks arcs and delays fire spread. In corrosive chemical environments, it also protects conductors, further lowering fire risks.

Advantage 2: High Reliability for Power Quality in Harsh Environments

Through structural and material optimization, ABC cables demonstrate superior environmental adaptability and operational stability, reducing outage duration and enhancing power supply quality.

Superior Weather Resistance for Complex Climates

The weather-resistant treatment applied to ABC cable insulation and conductors withstands extreme conditions including wind, rain, ice, snow, and temperature extremes. In complex regions like the rainy south or frigid north, their operational stability significantly outperforms bare conductors.

Strong Interference Resistance, Reduced External Damage

ABC cable insulation prevents direct contact with tree branches, while its bundled structure minimizes entanglement by foreign objects. External damage-induced outages are reduced by over 60%. Additionally, it requires lower clearance distances from municipal facilities, effectively avoiding interference.

Voltage Stability and Reduced Energy Loss

ABC cable insulation reduces corona losses by over 80%. Its low conductor resistance increases current-carrying capacity by 10%-15% compared to bare conductors. Over long-distance distribution, voltage drop is only 70%-80% of bare conductors, ensuring stable terminal voltage.

Advantage 3: Cost-Effectiveness and Reduced Lifecycle Costs

Compared to bare conductors and underground cables, ABC cables offer significant cost advantages throughout installation and operation, enabling substantial savings for enterprises.

Low Installation Costs and High Construction Efficiency

The bundled design of ABC cables eliminates the need for numerous insulators, reducing accessories by 70%. Weighing only 30% of bare copper conductors of equivalent cross-section, they can be manually installed, boosting construction efficiency by 50%. The installation cost per kilometer for low-voltage ABC cables is 60%-70% of bare conductors, far lower than underground cables.

Low O&M Costs and Extended Service Life

ABC cables have a lifespan of 25-30 years, 50% longer than bare conductors. With fewer faults, their average annual O&M costs are only one-third of bare conductors. The insulation layer also protects conductors from corrosion, further reducing maintenance expenses.

Compatible with legacy network upgrades, reducing renovation complexity

ABC cables can utilize existing utility poles for installation, eliminating the need for new pole construction. This significantly lowers civil engineering costs for renovating aging residential areas and rural grids. Simple construction shortens renovation cycles by 40%, making it the optimal choice for budget-constrained projects.

Advantage 4: Flexible Adaptability, Supporting Integrated Urban-Rural Electrification

With its compact structure and flexible installation, ABC cable adapts to diverse urban and rural distribution scenarios, supporting integrated electrification.

Adapting to Urban Densely Populated Areas, Enhancing Space Utilization

In narrow urban spaces, ABC cable's bundled structure saves space and reduces visual pollution. Requiring minimal clearance from buildings, it flexibly avoids obstacles, adapts to complex urban layouts, and contributes to urban beautification.

Supporting Rural Electrification and Solving Remote Area Power Supply Challenges

In rural areas with complex terrain and dispersed populations, ABC cables' lightweight design and flexible installation adapt to mountainous regions and farmlands. They eliminate the need for large-scale land leveling, reduce installation costs, effectively alleviate rural grid construction pressures, and contribute to rural revitalization.

Adapting to Diverse Scenarios and Expanding Application Scope

ABC cables also serve scenarios like streetlight power supply, temporary construction, and industrial park distribution: integrated lighting conductors simplify municipal projects; temporary installations offer easy, reusable setup/teardown; medium-voltage types handle industrial high-load and corrosive environments.

Typical Application Scenarios for ABC Cables

Low-voltage overhead distribution networks: ABC cables serve as the backbone for main and branch lines in urban residential communities, urban villages, and rural settlements, ensuring safe and stable daily power supply for residents.

Street lighting systems: ABC cables integrated with lighting conductors power streetlights on urban thoroughfares and rural roads, simplifying installation processes and minimizing space requirements.

Industrial and Commercial Distribution: For medium- and low-voltage distribution lines in industrial parks, logistics zones, and large shopping malls, ABC cables demonstrate strong weather resistance, handling high loads and complex industrial conditions.

Conclusion: ABC Cable—The Preferred Solution for Modern Power Distribution

In summary, Aerial Insulated Cable (ABC) has emerged as the upgrade direction for modern overhead power distribution systems due to its core advantages: ultimate safety, high reliability, cost-effectiveness, flexible adaptability, and eco-friendly aesthetics. Compared to traditional bare conductors, ABC cables fundamentally eliminate safety hazards and enhance power supply stability. Compared to underground cables, ABC cables significantly reduce installation and maintenance costs while accommodating a wider range of installation scenarios. In national key projects such as urban grid upgrades, rural electrification, and new energy integration, ABC cables are playing an irreplaceable role.